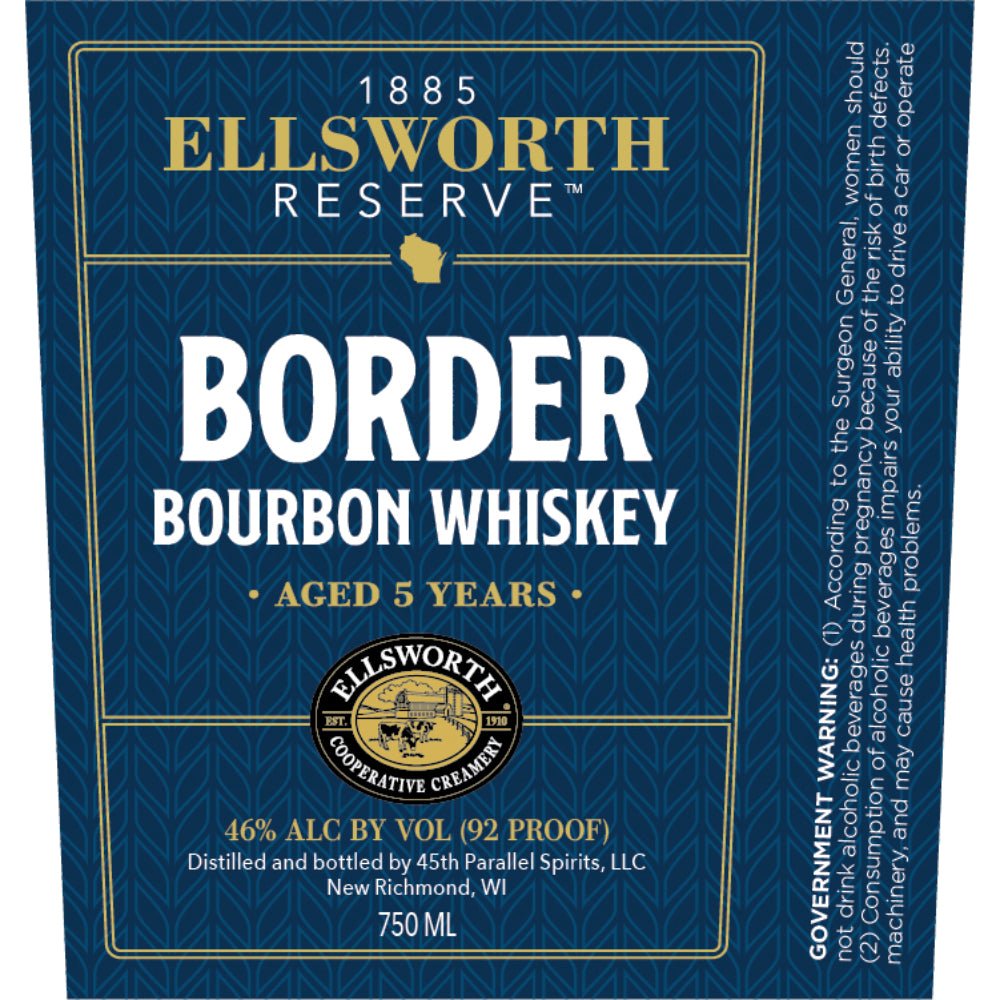

Ellsworth Reserve 5 Year Old Border Bourbon 45th Parallel Spirits

$ 0,00

Our “Full Circle” of Local Production

45th Parallel’s process is a full circle local production and begins when we pick up grain from Rusmar farm. We then mill, mash, ferment, and distill it all within our facility. Afterwards, the grain is shipped to another local farm where it is used as feed for livestock. Naturally, the livestock turn the grain into fertilizer for next year’s crops.

Slow Distillation

When you conduct slow distillation you can separate all the different components and respect your temperatures during the process. Today many “craft” distillers use a hurried approach that minimizes, or even rejects these frameworks.

Slow Maturation

When you understand that time is a factor you cannot control, you focus on the ones you can. Temperature and humidity are two very important elements in the maturation process. Many try to speed up the aging process by using higher temperatures and using smaller barrels. This results in the hard and disproportionate amount of tannins. There is no substitute for time. It is a fundamental part to achieve high-quality products.

Today many distillers care more about maturing their spirit quickly with wood extracts. A traditional slow maturation process results in a full-bodied flavor that can only be accomplished from years in high-quality wood barrels.

Time is constant and cannot be controlled. We don’t try to.

Fast Shipping with Professional Packaging

We can offer a variety of shipping options thanks to our long-term partnership with UPS FedEx DHL. Our warehouse staff is highly skilled and will wrap your goods according to our precise and accurate specifications. Before they are shipped the goods are carefully inspected and secured. We deliver to thousands of clients every day in a variety of countries. The fact that we're committed to becoming the biggest online retailer in the world is obvious. The warehouses are located situated in Europe as much as they are in USA.

Note: Orders containing more than one item will be assigned a separate processing period for each item.

Prior to shipment, all purchased products will be thoroughly inspected. Today, the majority orders will be sent within 48 hours. Expected delivery time is between 3 and 7 days.

Returns

The inventory is always changing and we cannot completely manage it because multiple stakeholders are involved, including our factory and warehouse. The stock levels may fluctuate at any given time. It is possible that the stock may run out after your order has been processed.

The policy is for 30 days. If it's been more than 30 days since you've bought the item We're sorry to say that we can't offer you a full refund or exchange.

You are able to return an item when it's unopened and is in the same state as the day you received it. You must have the item in the original packaging.

Related products

Tequila

Rye Whiskey

Single Malt Whiskey

10th Mountain American Single Malt Whiskey 10th Mountain Whiskey And Spirit Co.

Ready-To-Drink Cocktails

1800 Tequila The Ultimate Passion Fruit Margarita 1.75L 1800 Tequila

Ready-To-Drink Cocktails

1800 Tequila The Ultimate Margarita Original 1.75L 1800 Tequila

Single Malt Whiskey

10th Street Peated Single Malt Distiller’s Cut 10th Street Distillery

Uncategorized

Single Malt Whiskey

10th Street Peated Single Malt Whisky 10th Street Distillery

Single Malt Whiskey

Uncategorized

Tequila

Bourbon

Bourbon

Tequila

Uncategorized